Case

reactor for manufacture of nitrogen monoxide

2022-11-13T11:11:38+00:00

reactor for manufacture of nitrogen monoxide

The Page Description Nitrogen Oxides and Nitric Ac , but at high temperatures in the combustion chamber the reaction , One important use for nitric acid is the manufacture of Catalytic reduction of nitrogen dioxide by carbon monoxideThe reactor was lagged with 14 in of glass fiber insulation Helium and carbon monoxide were fed from pressurized Reactor For Manufacture Of Nitrogen Monoxidea reaction column for continuously converting nitrogen tetroxide into anhydrous nitric oxide of high purity with strong nitric acid as a coproduct according to the equation 3no2+h2o>no+2hno3 USA Reactor for the manufacture of nitric oxideA Beginner s Guide to NOx, NO and NO2 as Air Pollutants Mar 26, 2020 0183 32 Nitrogen oxides NO x is a collective term used to refer to nitrogen monoxide nitric oxide or NO and reactor for manufacture of nitrogen monoxideA reactor for the reduction of nitrogen oxides in gases, comprises a gas inlet, leading to a first reactor section which reactor section comprises a plurality of first fixed beds defining between Reactor and process for the decomposition of nitrogen

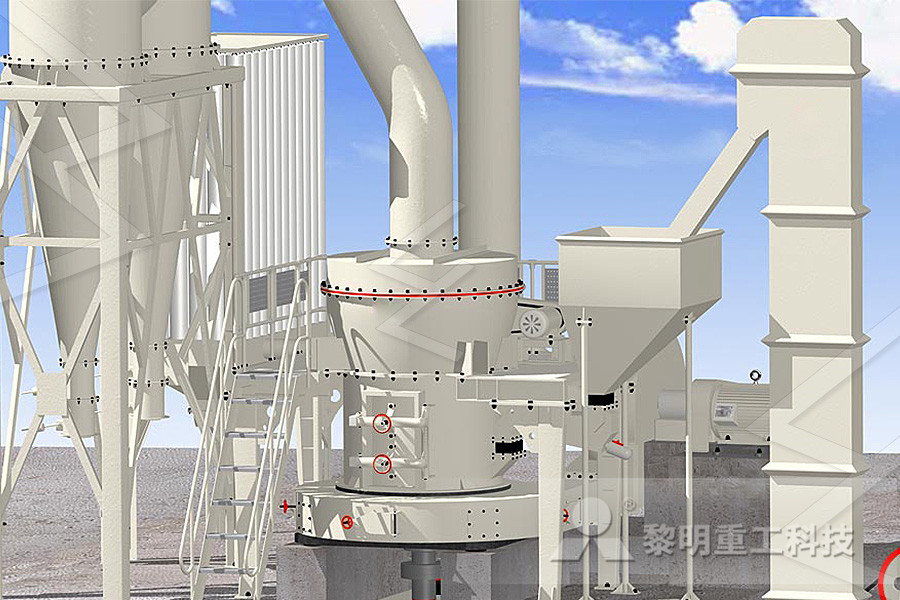

Microstructured reactors for gas phase reactions

As products nitrogen, nitrogen monoxide and also to nitrous oxide were found the latter at synthesis of phosgene to demonstrate the feasibility of a safe and ondemand A Reactor; Inlet pipe diameter = 0719 m Outlet pipe diameter = 0968 m Diameter of region where gauge is present = 1387 m Height of reactor = 15023 m Volume of reactor = Process Analysis and Plant Design for Manufacturing of LM Vertical Mill 18/09/2015; 10 Comments; Super User; 3 Tags; High drying efficiency, Low running cost, Good environmental effect LM Vertical Mill integrates crushing, drying, grinding, Reactor For Manufacture Of Nitrogen MonoxideThe invention claimed is: 1 A method for producing ammonium nitrate, comprising: providing a nonexplosive gaseous oxidiser feed comprising ammonia, steam and an oxidising gas to a Process for producing ammonium nitrate Orica Process Analysis and Plant Design for Manufacturing of nitrogen monoxide Here compressed air is mixed with anhydrous ammonia, fed to a shell and tube heat exchanger, reactor for manufacture of nitrogen monoxide

Nitrogen Monoxide an overview ScienceDirect Topics

Hermann W Bange, in Nitrogen in the Marine Environment (Second Edition), 2008 21 Climatic and biogeochemical relevance Nitric oxide or nitrogen monoxide (NO) is a colorless gas It has a boiling point (bp) of –1518°C (at 1 atm) and molecular weight of 300 g mol − 1Because it has an odd number of electrons, NO is a very reactive molecule (a socalled radical) (Greenwood and A novel rotary reactor was proposed for nitrogen oxides (NO x) reduction by carbon monoxide (CO) in order to avoid the oxygen inhibition effectNO x adsorption and reduction were separated into two different zones Nitrogen oxides reduction by carbon monoxide The production of NO x from air and air + O 2 is investigated in a pulsed powered milliscale gliding arc (GA) reactor, aiming at a containerized process for fertilizer production Influence of feed mixture, flow rate, temperature, and Ar and O 2 Plasma assisted nitrogen oxide production from The Page Description Nitrogen Oxides and Nitric Ac , but at high temperatures in the combustion chamber the reaction , One important use for nitric acid is the manufacture of reactor for manufacture of nitrogen monoxideThe Linde DCOOL Direct Injection Cooling System uses a proprietary nonfreezing injection system to cool fluids by injecting liquid nitrogen directly in the reaction vessel The direct injection of liquid nitrogen into the reaction vessel allows heat to be removed rapidly This helps shorten batch time and enhances productivity by reducing by Reactor Cooling Systems for Chemical Manufacturing Linde

USB2 Process for producing ammonium nitrate

A process for producing ammonium nitrate is disclosed, which process comprises exposing a gaseous oxidiser feed composed at least substantially of ammonia, steam and an oxidising gas to conditions whereby the ammonia is oxidised to produce a reaction mixture including nitrogen monoxide and water vapour The reaction mixture is cooled in a heat exchanger whereby the PDF On Dec 18, 2020, AbdElwahab Obaia and others published Manufacture of reactor for producing biogas from food waste and cattle manure Find, read and cite all the research you need on (PDF) Manufacture of reactor for producing biogas fromThe manufacture of nitrogen fertilisers represents by far the largest proportion of the use of nitric acid These fertilisers, generally with high nitrogen contents, provide the active nitrogen in the form of ammonium nitrate or as The Manufacture of Nitric AcidThe invention claimed is: 1 A method for producing ammonium nitrate, comprising: providing a nonexplosive gaseous oxidiser feed comprising ammonia, steam and an oxidising gas to a reactor; in the reactor, oxidising the ammonia of the nonexplosive gaseous oxidiser feed to produce a reaction mixture comprising nitrogen monoxide and water vapour; providing the Process for producing ammonium nitrate Orica The diagram shows some details of the manufacturing process (a) Nitrogen is obtained from the air a comparatively high temperature of 4500C is used for the industrial process, • iron powder is added to the reactor Stage 1 Ammonia reacts with oxygen from the air to form nitrogen monoxide and water 4NH 3 + 5O 2 4NO + 6H Stage 2 On Questions and Answers HABER PROCESSpdf Course Hero

Nitrogen Monoxide an overview ScienceDirect Topics

Hermann W Bange, in Nitrogen in the Marine Environment (Second Edition), 2008 21 Climatic and biogeochemical relevance Nitric oxide or nitrogen monoxide (NO) is a colorless gas It has a boiling point (bp) of –1518°C (at 1 atm) and molecular weight of 300 g mol − 1Because it has an odd number of electrons, NO is a very reactive molecule (a socalled radical) (Greenwood and Nitrogen oxides NO x (=NO + NO 2) have been identified as a type of atmospheric pollutant that result in a number of challenges in the modern ageNO x is generated by combustion machinery such as factories, thermal power plants, and vehicles and cause respiratory diseases and photochemical smog NO x are also precursors of fine particulate Evaluation on nitrogen oxides and nanoparticle removal A novel rotary reactor was proposed for nitrogen oxides (NO x) reduction by carbon monoxide (CO) in order to avoid the oxygen inhibition effectNO x adsorption and reduction were separated into two different zones in the proposed rotary reactor NO x in the flue gas was adsorbed onto the catalyst surface in the adsorption zone and then reduced by the reducing Nitrogen oxides reduction by carbon monoxide over semi motion detector OT presence people power sensor optical, Presence detector, 58x49x208mm, 1224V AC/DC, 2x Relay contact NC/NO, Cable with connector 10m, IP54, Plastic Motion and presence detectors Presence detector Radar Nitrogen monoxide detector, NO detector All industrial The center of any chemical process is the reactor, where chemical reactions are carried out to transform feeds into products Reactor design is a vital step in the overall design of a process It is important to ensure that the Reactors processdesign Northwestern

(PDF) Design of Ammonia Reactor ResearchGate

On the other, ammonia synthesis runs continuously and hence operates 24/7 Ammonia is formed inside a series of three fixed bed reactors where it converts syngas (hydrogen and nitrogen) into Removal of nitrogen oxides using a nonthermal plasma process (dielectric barrier discharge) combined with catalyst was investigated In this system, selective catalytic reduction of nitrogen oxides is affected by the operating condition of the plasma process and, thus, the characteristics of the plasma process were separately examined before combining the two Abatement of nitrogen oxides in a catalytic reactor cally bound nitrogen contribute to over 50% of total emissions of NO x, according to some estimates The nitrogen content of US coal ranges between 05% and 2% and that of residual fuel oil between 01% and 05% In many circumstances, the most costeffective means of reducing NO x emissions will be to use lownitrogen fuels such as Nitrogen Oxides: Pollution Prevention and Control B 627628, Steel Chamber Tower Mumbra Panvel Road, Kalamboli Maharashtra, India; 022 022 0224970 7929 +(91)Home [reactorco] 4NH 3 % 5O 2 6 4NO % 6H 2O 02/98 Inorganic Chemical Industry 881 88 Nitric Acid 881 General 12 In 1991, there were approximately 65 nitric acid (HNO 3) manufacturing plants in the U S with a total capacity of 11 million tons of HNO 3 per year The plants range in size from 6,000 to 700,000 tons perAP42 88 Nitric Acid Production US EPA

Plasma Nitrogen Oxides Synthesis in a MilliScale Gliding

Nitrogen fixed in the form of nitrogen oxides is essential to produce fertilizers and many other chemical products, which is vital to sustain life The performance of a milliscale gliding arc reactor operated under atmospheric pressure has been studied for nitrogen oxides synthesis In this work, the electrical and process parameters of the gliding arc reactor, such A chemical reactor or reaction vessel are vessels design to facilitate chemical reaction among various raw chemicals, known as reactants Reaction Vessels are also used for other processes such as solids dissolution, product mixing, distillation, crystallization, liquid/liquid extraction and polymerization Reactors are also identified based on Chemical Reactor ManufacturerSS ReactorJacketed motion detector OT presence people power sensor optical, Presence detector, 58x49x208mm, 1224V AC/DC, 2x Relay contact NC/NO, Cable with connector 10m, IP54, Plastic Motion and presence detectors Presence detector Radar Nitrogen monoxide detector, NO detector All industrial Nitrogen Monoxide is a vasodilating agent used in the treatment of hypoxic respiratory failure in premature neonates For the treatment of term and nearterm (>34 weeks) neonates with hypoxic respiratory failure Nitrogen Monoxide is also used to associated treatment for these conditions: Hypoxic Respiratory FailureNitrogen Monoxide Uses, Dosage, Side Effects, FAQ The center of any chemical process is the reactor, where chemical reactions are carried out to transform feeds into products Reactor design is a vital step in the overall design of a process It is important to ensure that the Reactors processdesign Northwestern

(PDF) Design of Ammonia Reactor ResearchGate

On the other, ammonia synthesis runs continuously and hence operates 24/7 Ammonia is formed inside a series of three fixed bed reactors where it converts syngas (hydrogen and nitrogen) into N2 (Nitrogen) has a lot of industrial applications and is highly demanded by many major industries In order to cater to this high demand for nitrogen, AtmosPower offers its exclusive Nitrogen Plants based on the well PSA Nitrogen Gas Plant Manufacturer in 1 天前 Atmospheric nitrogencontaining particles decrease visibility NOx can react to form nitrous oxide (N 2 O), which is a greenhouse gas, and contribute to global warming Coal usually contains between 05 and 3 percent nitrogen on 87 Nitrogen Oxides (NOx) Emissions As a result, appropriate nitrogen safety precautions must be followed by nitrogen gas manufacturers and users Common Industrial Uses of Nitrogen Gas The manufacture of nitrogen gas has countless applications, especially How Is Nitrogen Produced for Industrial Cost effective onsite nitrogen and oxygen generators Peak is a global leader in the design, manufacture and support of high performance nitrogen and oxygen generator systems for manufacturing processing Cost effective nitrogen generator systems