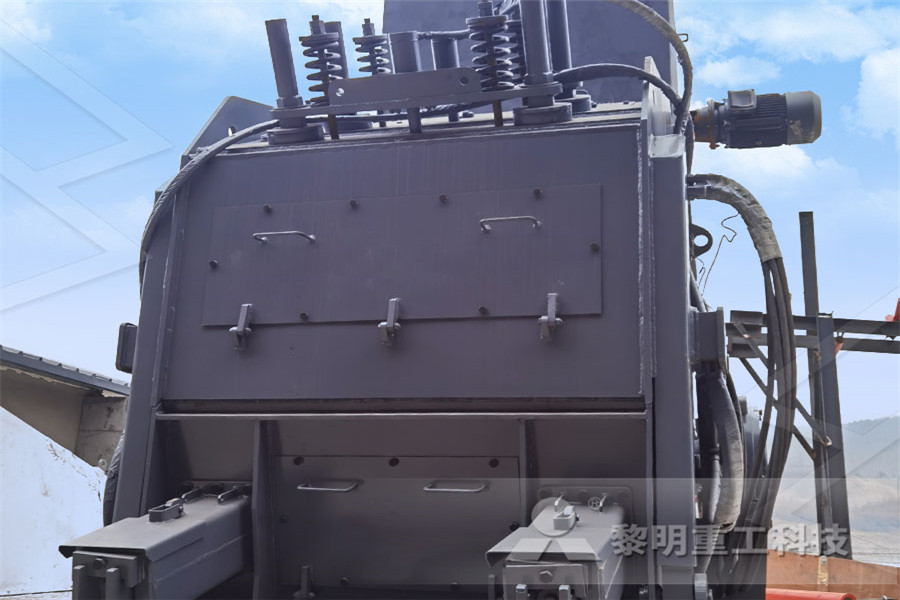

Case

gyratory primary crushers

2019-09-19T05:09:09+00:00

Gyratory Crusher Explained saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years) A primary Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a Gyratory Crushers Mineral ProcessingPrimary gyratory crusher spare parts Outotec is the industry leader in manufacturing gyratory crushers with over sixty years of experience As the popular crushers, our primary Primary gyratory crusher parts OutotecA gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size Gyratory Crusher Hazemag North AmericaThe primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall The movable cone of gyratory crushers suspends from a beam at the upper part of Gyratory Crusher l Introduce, Working Principle

Primary Crusher an overview ScienceDirect Topics

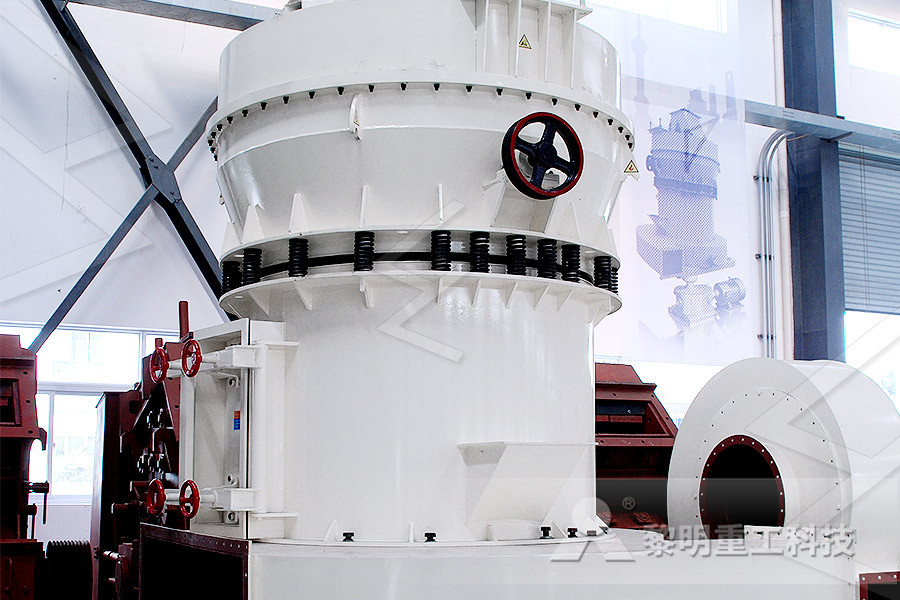

Primary gyratory crushers are used in the primary crushing stage Compared to the cone type crusher, a gyratory crusher has a crushing chamber designed to accept feed material of a Superior™ MKIII primary gyratory crushers all can include SmartStation, which combines innovative monitoring tools Tools such as **VisioRock® and VisioTruck® along with Superior™ MKIII Series primary gyratory crushers The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions It is designed so that you can easily access and Gyratory Crusher (TS) for harsh environments32 行 MAX Note1 Capacities shown are based on an assumed feed size distribution which 100% of feed passes 90% of feed opening and 80% of feed passes 42% of feed opening Note2 Capacities shown are based on Gyratory Crusher (GY model) Crushing/Grinding The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions It is designed so that you can easily access and Gyratory Crusher (TS) for harsh environments

Gyratory Crushers Sandrock Mining

+8615797717019 Contact Now! Gyratory Crushers Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage Gyratory crushers have an oscillating shaftCG850 i Gyratory crusher Sandvik CG850i crusher is built to be robust, reliable and efficient Connected to My Sandvik, they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is Sandvik CG850 Primary Gyratory Crusher With A gyratory crusher consists of a solid main shaft housed within a hollow body with vertically sloping sides When the crushing surfaces come into contact with the material it is crushed, and the crushed products fall through the discharging opening Like the jaw crusher, the largest gyratory crusher can handle boulders up to 15 m in lengthBasics of gyratory crushers IMS Engineering (Pty) Ltd Gyratory Crusher (GY model) FEATURES Excellent Design ・Design is a combination of the most modern engineering techniques ・Our newest 60109 GY provided to Kansai Airport Project phase 2 was divided into many Gyratory Crusher (GY model) Crushing/Grinding Features of the Gyratory Crusher High capacity per dollar of investment, Annular discharge opening minimizes slabbing; makes for more cubical product Shape of receiving openings favourable for slabby material Gyratory VS Jaw Crushers: Advantages

thyssenkrupp Mining Technologies

thyssenkrupp Mining TechnologiesGyratory crushers, while similar to jaw crushers, differ in that they are conicallyshaped with a concave surface and conical head The movement in gyratory crushers is generated through an eccentric arrangement Trio ® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology and gyratory crusher designPrimary gyratory crushers (KKD) are designed for the primary crushing of ore and rock products at the first crushing stage Reduction gyratory crushers (KRD) are designed for the use at the second crushing stage in 4stage crushing circuitsUZTMKARTEX Primary and reduction gyratory crushersGyratory Crushers are a primary crusher used in mining and ore processing Similar in concept to a jaw crusher: • Concave surface • Conical Head Gyratory Crusher,Screen,Separator,Primary Gyraory Crusher Gyratory Primary Crusher Crusher Mills, Cone Crusher, Trio ® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology and manufactureing that provides high performance, reliability, and costeffective solution TG Series Gyratory Crushers are typically applied in large tonnage mining and aggregate plants LITERATURE FEATURES APPLICATIONSGyratory Crushers Diamond Equipment Group

Gyratory Crushers SolidsWiki

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory cone crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory cone crushers can be used for primary or secondary crushingOur comprehensive range of replacement crusher parts to suit primary gyratories are certified to meet the OEM specification under our Lloyds Register quality system Furthermore, our premium range of primary gyratory crusher Primary Gyratory Parts Gyratory Crusher PartsHow do a gyratory crusher work? A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head with both the surfaces are typically lined with manganese steel liners The inner cone has a slight circular movement, but it does not rotate The movement is generated by an eccentric arrangementHow do a gyratory crusher work? amcrushersTAKRAF’s range of primary crushing plants Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on material properties and required throughputsPrimary Crushing Plants TAKRAF TAKRAF GmbH Primary gyratory crushers are easily the hardest working piece of fixed plant on a mine site The gateway between extraction and processing, they bear the brunt of continuous operation, high feed volumes, and are subject to rock particles of TLC for Primary Crushers E MJ

What Is Primary, Secondary, and Tertiary

Eagle Crusher consistently leads the industry in new product innovations We stand by our products with unsurpassed service and support to make your job easier Get serious Get Eagle Crusher • Durability and Sandvik CG830i crusher offer excellent reliability and safer faster maintenance – up to 30% faster than competing crushers A robustly designed onepiece main shaft and reinforced shells are made for tough use The onepiece spherical Sandvik CG850 Primary Gyratory Crusher With Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley , appliances and dry oil, thin oil lubrication system components etc A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory Gyratory Crushers SolidsWiki A primary gyratory crusher consists of a concave surface and a conical head; both surfaces are typically lined with manganese steel The Construction Technology offers the complete range of primary gyratory crushers to meet all application requirement Machine size* Feed opening mm (in) Mantle diameter mm (in) 4265 1065 (42) 1650 (65)Application guide SUPERIOR® primary gyratory crusher Primary crushing plants are the first step in material processing and/or link between mining truck and belt conveyor, train or road TAKRAF’s range of primary crushing plants Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on Primary Crushing Plants TAKRAF TAKRAF GmbH

TLC for Primary Crushers E MJ

TLC for Primary Crushers Safety is paramount when working on such large, heavy pieces of equipment (Photo: Outotec) A gyratory crusher is a significant investment for any mine Take care of it and it will serve you well Primary gyratory crushers are easily the hardest working piece of fixed plant on a mine site The crushing of material into smaller loads is usually undertaken in two steps, starting with the primary crusher that includes jaw crushers, hammer mill crushers, and gyratory crushers Larger stones or mineral ores are used to produce smaller material Where the material is not reduced sufficiently in the primary crusher, it is then crushed Primary and secondary crushers Welding AlloysGyratory crushers: Soft to very hard: Abrasive: Dry to slightly wet, not sticky: 4/1 to 7/1: Heavy mining, quarried materials: Horizontal shaft impactors: In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, Rock Crusher Eastman Rock CrusherOpen pit mining worldwide utilizes gyratory crushers as the primary crushing circuit that feeds the mills In some cases, the mantles are changed approximately every seven weeks at a cost of approximately $150,000 each time It is expected that the present technology will result in at least one less changeout per year At one large open pit Crusher Closed / Open Side Setting Program Global EARTHTECHNICA CO, LTD Taking full advantage of our promising technologies for 'CRUSHING, GRINDING AND SEPARATION', we are globally developing four businesareas consisting of Crushing grinning, Recycling, Powder processing and Casting products to meet the customer needsCrushing/Grinding EARTHTECHNICA CO, LTD

gyratory crusher design

Gyratory crushers, while similar to jaw crushers, differ in that they are conicallyshaped with a concave surface and conical head The movement in gyratory crushers is generated through an eccentric arrangement Trio ® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology and