Case

cement Mining Preparation Plants

2023-03-20T00:03:35+00:00

Cement Plant Cement Manufacturing Plant EPC Project

The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize The mass and energy balances for the cement plant concepts with carbon capture were used furthermore to evaluate the key plant performances The designs were optimized by Cement Plant an overview ScienceDirect TopicsOur Production Equipment AGICO Cement is a cement plant manufacturer with production capacity of 30,000 tons of equipments and structure parts and 20,000 tons of casting Cement Plant, Cement Equipment Cement Plant SAFAS has a production line dedicated to the production of wearresistant castings for grinding mills, sandblasting components and shot blasting systems, asphalt and concrete Cement Plants / Mining SAFASThe raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing: the limestone and other materials are crushed into small Preparation Of Cement Raw Material Cement Mill,

Cement Production an overview ScienceDirect Topics

Abstract Cement production is an energyintensive process The cost of energy constitutes more than 60% of the cost of the cement; hence cement plants have to consider minimizing the cost Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, The Cement Manufacturing Process Advancing MiningBut unlike the urban and industrial revolutions experienced elsewhere, the concrete that underpins life here is made not with Portland cement, but calcined clay Or perhaps you are in How is cement made in 2050 – what will plants look like?The cement manufacturing process involves three components: the mining and preparation of inputs; the chemical reactions that produce clinker; and the grinding of clinker with other Cement Industry an overview ScienceDirect Topics Cement Plant Construction Management Services were provided by PENTA for this new international $200 million range greenfield EPCM project 3000mt New Clinker Line PENTA Engineering Company partners with sister Cement Plant Construction Management

Cement Euipment Overview Cement Making Machines

Cement mill is another necessary cement equipment of the cement plant After raw material crushing, cement mill plays vital role in the further cement manufacturing process Cement ball mill, vertical cement mill, and cement roller press are common types of cement grinding plant cement ball mill Cement mill has two functions of the cement Ammann concrete mixing plants are built with highquality materials and engineered to guarantee component life The plants are designed for high productivity and are available in stationary, semimobile and fully mobile versions Other options include precast component and high performance plants All plant types also integrate modular designs that provide flexibility so you can customiseCONCRETE MIXING PLANTS AmmannAbstract Cement production is an energyintensive process The cost of energy constitutes more than 60% of the cost of the cement; hence cement plants have to consider minimizing the cost of energy when planning production However, there are several challenging issues regarding the production planCement Production an overview ScienceDirect TopicsBut unlike the urban and industrial revolutions experienced elsewhere, the concrete that underpins life here is made not with Portland cement, but calcined clay Or perhaps you are in Chile, where the cement plants now process the region’s massive deposits of mine tailings – over a century’s worth – into enhanced cementitious materialsHow is cement made in 2050 – what will plants look like? Modernization of cement plants is one of the main ways to increase business competitiveness: project finance and EPC contractsCement plant modernization: energy efficiency and

Cement Plant Construction Management

Cement Plant Construction Management Services were provided by PENTA for this new international $200 million range greenfield EPCM project 3000mt New Clinker Line PENTA Engineering Company partners with sister The country has 12 integrated cement plants and six cement and slag grinding facilities, as detailed in Figure 4 and Table 1 The bulk of the cement production sites are in the northwestern Provinces of North West Province and Gauteng The western coastal State of Kwazulu Natal also has a relatively high number of cement plantsThe cement industries of southern Africa Global CementMethods Of Grinding Iron Ore Preparation Plant 13/09/2020 Methods Of Grinding Iron Ore Preparation Plant Beneficiation Plants And Pelletizing Plants For Utilizing pelletizing plant 12 Outline of iron ore production The production of iron and steel in China has Grinding is a subprocess of finely grinding ore in advance, such that the ground output can be separation is a methods of grinding iron ore preparation plant MAURIZIOThe mass and energy balances for the cement plant concepts with carbon capture were used furthermore to evaluate the key plant performances The designs were optimized by performing a heat integration analysis (using pinch technique) for maximization of the overall energy efficiency (Smith, 2005)As an illustrative example, Figure 1 presents the hot and cold composite curves Cement Plant an overview ScienceDirect TopicsAmmann concrete mixing plants are built with highquality materials and engineered to guarantee component life The plants are designed for high productivity and are available in stationary, semimobile and fully mobile versions Other options include precast component and high performance plants All plant types also integrate modular designs that provide flexibility so you can customiseCONCRETE MIXING PLANTS Ammann

Preparation Of Cement Raw Material Cement Mill,

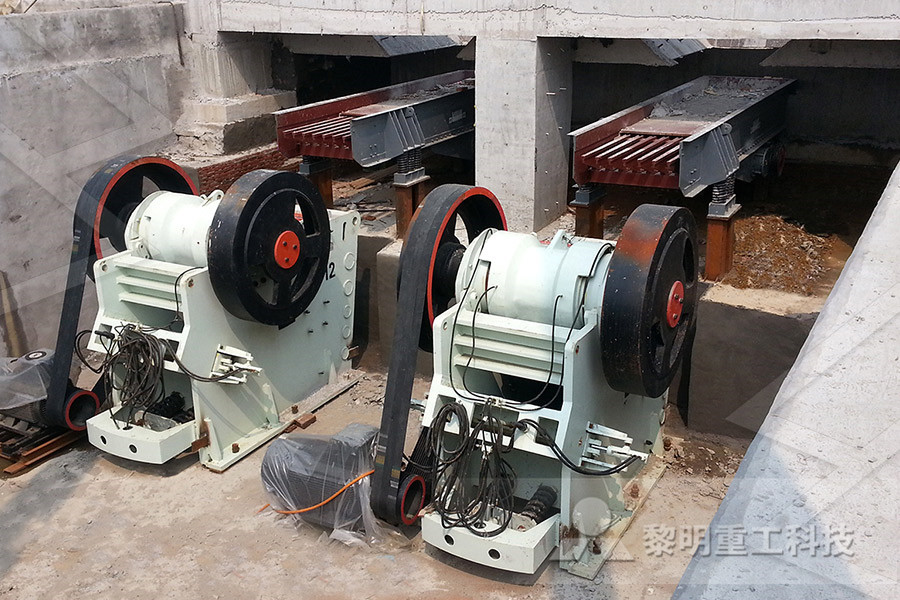

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, jaw crusher, impact crusher, etc Mixing: according to the requirement of clinker, compound Our team offers financing and engineering design for cement plants around the world, helping companies implement innovative technical solutionsCement plant design under EPC contract esfccompanyThere are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as “ clinker ,” together with some 5 percent of gypsum (to control the time of set of the cement)cement Extraction and processing Britannica Simem Underground Solutions provides advanced equipment for the production of concrete, pastefill, shotcrete, and cemented rockfill product for mining operations worldwide Our custom mining solutions are designed specifically for your project, timeline, and specifications to ensure a mining operation moves forward without interruption CRF PlantsCustom Mining Solutions Concrete, Pastefill, Cemented PA Cement Production Offices 10 Plants 9 Terminals 7 Economic Data • Clinker capacity: 59 million metric tons • Cement production: 39 million metric tons • Cement consumption: 27 million metric tons • Cement employees: 811 in 2015 from 1,490 in 1997 • Cement concreterelated employees: 19,368 with a payroll of $998 millionPENNSYLVANIA CEMENT INDUSTRY

(PDF) Water Footprint Assessment Study of

Cement Industry has been making efforts to improve water efficiency NCB has taken up a study to carry out water footprint assessment of cement plants as per ISO 14046:2014 This paperSelected Mining Equipment Manufacturer Contractors Site map +86 28 g English Chinese Russian keyword KEYWORODS: concrete support con Home Mineral Processing EPC Mineral Coal Washing Plant, Coal Preparation Mining wastes, also known as extraction wastes, overburden or coal spoil (CS), are rocks and minerals generated from the mining and preparation plants resulting from opening up the main mineral deposit, composed mainly of cap and interlayer rocks They represent an average of about 20% of the total mass of waste ( Hycnar and Bugajczyk, 2004 )Coal waste: handling, pollution impacts and utilizationThe Ramla cement plant (see Fig 1 for an aerial photo of the plant) has been in operation for 46 years The original process at the Ramla cement plant to produce cement from limestone, which is the base material of cement, was a socalled wet line process The original wet line had a capacity of 1,800 TPD (Tons Per Day)Cement Plant an overview ScienceDirect Topics Below Figure 4: Map of Southern Africa showing location of integrated and grinding cement plants, both active and planned Countries are colourcoded by active integrated capacity and cement grinding capacity Botswana Since Botswana became independent from the UK in 1966, the country has been one of the most politically stable in AfricaThe cement industries of southern Africa Global Cement

Construction of a mining and processing plant under ЕРС

Mining and processing plant construction The Spanish company ESFC Investment Group offers financing and construction of mining and processing plants under EPCcontract We offer project finance and investments: from €50 million with a loan duration up to 20 years Description Industries and Services PublicationsSpecial Publications Background Facts and Issues Concerning Cement and Cement Data OF20051152 Historical Statistics for Mineral and Material Commodities in the United States Data Series 140 Cement Materials in Use in US Interstate Highways FS20063127Cement Statistics and Information US Geological Survey Those new performance standards were designed to further reduce emissions at new coal preparation and processing plants that process more than 200 tons of coal per day Coal preparation and processing plants break, crush, screen, clean and/or use heat to dry coal at coal mines, power plants, cement plants, coke manufacturing facilities, and Coal Preparation and Processing Plants New Source 09The Cement Plant Operations Handbook, 7th Editionpdf Free ebook download as PDF File (pdf), Text File (txt) or read book online for free preparation of a draft report, Extensive drilling has confirmed quantity, mineralogy, variation, mining and legal availability Class Bor probable reserve s Sufficient drilling allows 09The Cement Plant Operations Handbook, 7th Edition Coal handling plant of thermal power station –A New Approach By Makarand Joshi 10 Abstract: Shut down can be defined as scheduled down period for a plant for scheduled maintenance for an extended period of time Shutdowns provide unique opportunities to a maintenance department not normally available during standard operation or even duringShut down management Plant Maintenance

coal handling and preparation plant pcements

Coal handling and preparation plant Mongolian Mining With its Coal handling and preparation plant (“CHPP”) in operation at UHG since 2011, MMC is the first washed coal producer of the country The CHPP, the first of its kind in Mongolia and set to be one of the largest coking coal processing plants in the world,Coal Mining And Coal Preparation Plants Coal Mining And Coal Preparation Plants MENU 1 A Bit of Good News For Coal? (Aug 28, 2014) Turn Out The Lights, The Party Is Over (Apr 21, 2014) Coal, The Black Fuel, Struggles in 2013 (Feb 17, 2013) Everything Affects Weather Early Results Of More Detailspreparation plants mining You might think of a cement manufacturing facility as an extension to a mining operation, as cement plants are typically located central to the minerals required to make the cement, which saves the transportation costs and reduces the price of the cement Limestone is one of the key minerals used in cement makingAre You Mining Minerals for Cement, or for Concrete?