Case

ball mill grinding of the material

2022-04-18T11:04:46+00:00

Ball Mill an overview ScienceDirect Topics

Grinding is an energy intensive process and grinding more finely than necessary wastes energy Cement consists of clinker, gypsum and other components mostly more easily ground than The classifier delivered 33 T of sand per hour The total ballmill feed was therefore 4037 T per hr or 550 per cent, of the original feed Two Stage Ball Mill Grinding Theory Crushing Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter), which effectively grind the ore The material that is to be ground fills the voids between the balls The tumbling balls Ball Mill an overview ScienceDirect TopicsBalls – usually manufactured from manganese alloy steel, but the material depends upon for what material the mill will grind (chrome steel alloy and rubber also available) The size of the balls Ball Mill Explained saVRee Ball Mills In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to Ball Mills Mineral Processing Metallurgy

(PDF) Grinding in Ball Mills: Modeling and

There are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; Ball mill used in the process of fining material Ball mill,like hammer crusher, and impact crusher, grinds material through the rotation of a cylinder with steel grinding balls, Ball mill used in the process of fining material For different material grinding methods, mill structure, operating conditions, and mills with different media shapes, the grinding medium charge ratio has a certain suitable range Comparative Analysis of Rod Mill and Ball Mill One of the important problems for ball mills is the problem of reducing the efficiency of grinding material The degree of grinding of materials in ball mills ensures the quality ofImprovement of the structure of a ball mill with the Large VS Small Grinding Balls Two tests with closedcircuit crushing are reported to show the efficiency of the ballmill when charged with large and with small balls Test No 12 shows a production of 63 T of minus 200mesh Ball Mill Grinding Theory Crushing

Ball Mill Ball Mills Wet Dry Grinding DOVE

The Grinding Balls will grind the material into powder size of 20 to 75 micron In mining operations, this will allow for the liberation of gold and other precious metals that are hosted by the rocks Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties, specification and advantages The grinding ceramic ball mill uses different ball mill ceramic liner types according to production needs to meet different needs The finess of ceramic ball mills depend on the grinding time The electrohydraulic machine Ceramic Ball Mill For Grinding Materials FTM The production of Ball Mill Grinding Balls adopts a single refining process, which effectively ensures the stability of the material Before the furnace, after the furnace, semifinished products, and finished products, advanced spectral detection is used to ensure the longterm stability of chemical composition and performanceBall Mill Grinding Balls AGICO CEMENTRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only Ball Mill RETSCH powerful grinding and homogenization Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball Mill Working Principle And Main Parts GitHub Pages

Types of Ball Mill Machine Meet Your Industrial Grinding

Ball Mill Principle The ball mill machine is mainly composed of cylindrical cylinder, end cover, bearing and big gear ring Cylinder: The cylinder is filled with a ball mill grinding media (steel balls or steel cylpebs) with a diameter of 25mm150mm The loading capacity is 25%50% effective volume of the whole cylinderThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batch The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short Planetary Ball Mill PM 100 RETSCH highest fineness This will provide a better process of grinding the material in the ball mill The study used the analysis of the features of the ball mill designs, literature and patent review of existing ways to Improvement of the structure of a ball mill with the A ball mill is one kind of grinding machine,and it is a device in which media balls and solid materials (the materials to be ground) are placed in a container (PDF) A Survey on Troubleshooting of Closed Circuitmill/ ball mill study materialmd at master mill The grinding ceramic ball mill uses different ball mill ceramic liner types according to production needs to meet different needs The finess of ceramic ball mills depend on the grinding time The electrohydraulic machine Ceramic Ball Mill For Grinding Materials FTM

Grinding in Ball Mills: Modeling and Process

The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 Lcapacity grinding chamber made of an abrasionresistant elastomer, put in vibrating motion by hightensile steel springs [28] The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automatically fall and impact The working principle of ball mill Meetyou Carbide As for the dry grinding method, the moisture of raw material can affect ball mill capacity and quality The higher the moisture content of the milled material will cause saturated or greasy so that the capacity and quality of ball Factors That Affect Ball Mill Grinder Capacity Tube mill can grind finer products than the conventional ball mill Their construction is also simple and generally used for grinding hard material Tube mill has a higher length/ diameter ratio as compared to Ball mill Rod mill: This is a modification of the tube mill Instead of balls or pebbles, rods are used as grinding materialConstruction and Working of Ball Mill Solution Pharmacy Ball mill is an efficient tool for grinding many materials into fine powder The ball mill is used to grind many kinds of mine and other materials, or to select the mine It is widely used in building material, chemical industry, etc There are two types of grinding: the dry process and the wet process It can be divided into tabular type and Ball mill used in the process of fining material

Planetary Ball Mill PM 100 RETSCH highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batch The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short The object of research is the design of a ball mill for grinding dry materials, the subject of research is the efficiency of grinding material based on improving the design of a ball millImprovement of the structure of a ball mill with the 1 Rough: Steel grinding balls use bearing scrap steel as raw material, with a large amount of copper, molybdenum, nickel and other precious metal elements added to make the structure more compact After checking, Choose the Best Grinding Steel Balls for Your A ball mill is one kind of grinding machine,and it is a device in which media balls and solid materials (the materials to be ground) are placed in a container (PDF) A Survey on Troubleshooting of Closed Circuitmill/ ball mill study materialmd at master mill Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic Ball Mill Grinding William Boulton

What Is a Ball Mill? Blog Posts OneMonroe

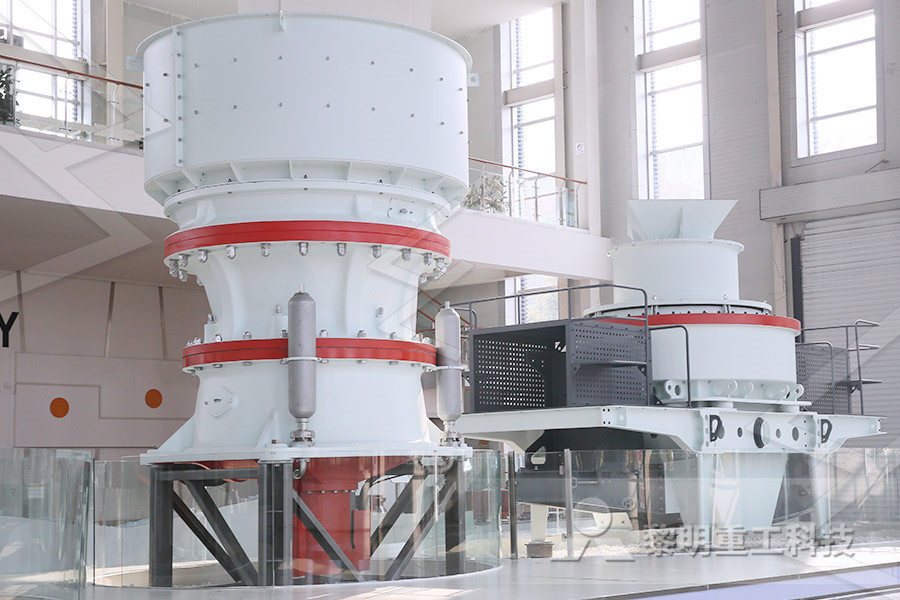

Overview of Ball Mills As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material It consists of a hollow compartment that rotates along a horizontal or vertical axis It’s called a “ball mill” because it’s literally filled with balls Materials are added to the ball mill, at The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automatically fall and impact The working principle of ball mill Meetyou CarbideA Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground Ball millMagnesium millBeneficiation ball millHorizontal Ball Mill Material Crusher Mills, Cone Crusher, Jaw Crushers As for the dry grinding method, the moisture of raw material can affect ball mill capacity and quality The higher the moisture content of the milled material will cause saturated or greasy so that the capacity and quality of ball Factors That Affect Ball Mill Grinder Capacity The starting point for ball mill media and solids charging generally starts as follows: 50% media charge Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or Ball Mill Loading Dry Milling Paul O Abbe

Ball mill used in the process of fining material

Ball mill is an efficient tool for grinding many materials into fine powder The ball mill is used to grind many kinds of mine and other materials, or to select the mine It is widely used in building material, chemical industry, etc There are two types of grinding: the dry process and the wet process It can be divided into tabular type and Grinding balls for mining are generally used to break down secondary materials such as rock, cement and stone during the extraction of ores and metals AISI steel grinding balls for ball mill applications typically have a tolerance of Stainless steel grinding balls for mining / ball mill This will provide a better process of grinding the material in the ball mill The study used the analysis of the features of the ball mill designs, literature and patent review of existing ways to Improvement of the structure of a ball mill with the 1 Rough: Steel grinding balls use bearing scrap steel as raw material, with a large amount of copper, molybdenum, nickel and other precious metal elements added to make the structure more compact After checking, Choose the Best Grinding Steel Balls for Your